‘Appreciate the danger’ of eye injuries

Encouraging worker PPE compliance

Providing workers with appropriate hazard-based eye protection is critical to injury prevention, notes Larry L. Jackson, chief of the Injury Surveillance Team for the Surveillance and Field Investigations Branch of NIOSH’s Division of Safety Research. However, this does not necessarily mean workers will use the provided personal protective equipment.

“Employers and workers often do not understand or appreciate the danger that hazards may pose to their vision,” Jackson said. “Also, if [workers] recognize that there is a hazard, they may not believe that it will impact them.”

Worker behavior

Many workers incorrectly believe one type of PPE will protect them from all eye injuries. According to the National Safety Council’s “Fundamentals of Industrial Hygiene,” 6th edition, some workers believe their corrective eyewear can protect them from injury, giving them a false sense of security.

Jackson said workers also may be unaware of the potential severity of eye injuries, which are “often perceived as only being minor.” In truth, the eye is much more likely to suffer permanent injury than a body part such as a finger because the unique tissues that make up the eye are not present elsewhere in the body.

Another factor leading to non-compliance is the belief that eye protection reduces productivity or safety in other areas, such as fogging leading to a fall, Jackson said. Additionally, some workers find eye protection uncomfortable or unstylish.

To encourage worker compliance, “employers should explore the many options for acquiring eye and face protection and involve workers in the selection of the products used,” Jackson recommended. “Offering workers a selection of eyewear styles may improve fit, coverage and comfort while allowing workers personal style choices.”

More information

From CDC: Each day more than 2,000 U.S. workers receive some form of medical treatment because of eye injuries sustained at work. More than 800,000 work-related eye injuries occur each year.

Education and intervention

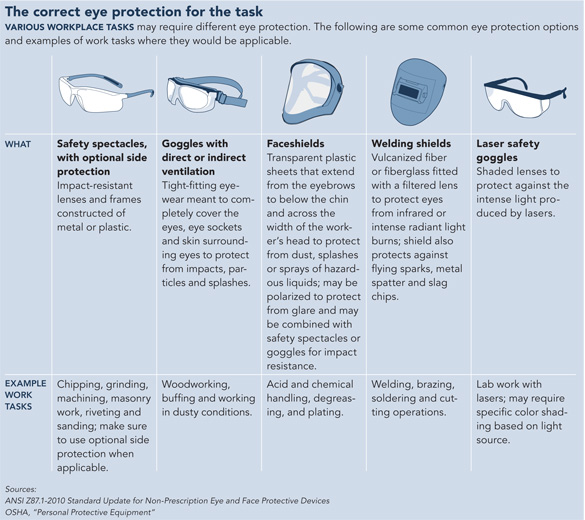

Employers also need to train workers on the proper eye protection for each hazard, Jackson said. For example, a construction worker who readily wears safety glasses while performing carpentry work may be unaware that eye protection must be worn when working with cement, which in powder or wet form can cause severe alkaline burns. Jackson suggests safety professionals follow the following guidelines when updating or creating an eye safety program:

- Review applicable OSHA eye safety standards and learn about common eye safety hazards in their industry.

- Identify hazard sources by walking through a work area and speaking with employees, including asking about hazards at all times of the day.

- Evaluate ways to mitigate eye safety hazards at the root cause, reducing the need for employees to use PPE.

- Look to the ANSI standards for each hazard to determine appropriate eye protection.

- Consult with workers on their eyewear preferences, and offer a variety of styles and sizes to increase the likelihood that employees will find the eyewear appealing.

- Incorporate employee input into training programs and written eye safety plans.

- Ensure supervisors and health and safety staff serve as role models when implementing or updating an eye safety plan by wearing the same eye protection as employees.

Ultimately, safety professionals should establish a culture where eye protection is the norm. “Culturally, wearing eye protection must become equivalent to a construction worker wearing a hard hat – a symbol of who they are and what they do, one that they don’t leave home without, and that they can’t start work without,” Jackson said.

A debilitating outcome

Not wearing eye protection can result in permanent blindness. Edward Bernacki, professor of medicine and chair of the joint committee on health, safety and the environment for the Johns Hopkins Health System and University in Baltimore, described an incident in the 1990s in which a graduate student who was not wearing eye protection suffered permanent blindness following a lab explosion. The individual was unable to work in the lab again, he said.

Sudden, permanent vision loss can take a serious toll, noted Lauri Dishman, manager of counseling services for Second Sense, a nonprofit blindness counseling organization based in Chicago. “Being blind is difficult for everyone,” Dishman said, “but for adults who are newly blind [or visually impaired], it can be a very big stigma. They typically have to go through all the steps of grieving in the post vision-loss process.”

To encourage workers to always use eye protection, Anita Stone, safety manager for Johns Hopkins Medicine, recommends sharing personal stories about the damaging effects of eye injury and vision loss. Stone said it is important to remind workers how something simple can save them hardship later in life. “It takes only one injury to change the rest of your life,” she said. “There are only so many things in life you can control, but this you can. Just taking that one step to put on your PPE can make a major difference.”

Optical radiation and bystanders

Workers performing job tasks are not the only ones exposed to eye safety hazards. In welding operations, the risk of welder’s flash – when the ultraviolet light of the electric arc injures the eye – is greater for helpers and bystanders because the welders are more likely to be wearing appropriate eye protection, according to the National Safety Council.

Other forms of optical radiation may occur in settings such as labs that use lasers or infrared radiation. In these settings, safety professionals “should also ensure that assistants, nearby workers, and site visitors either wear the appropriate radiation protector, are screened from the radiation source or are restricted from accessing the active work area,” said Larry L. Jackson, chief of the Injury Surveillance Team for the Surveillance and Field Investigations Branch of NIOSH’s Division of Safety Research.

The Johns Hopkins University Whiting School of Engineering in Baltimore has implemented a laser safety program to help protect employees. Frances Humphrey-Carothers, associate director for Health, Safety and Environment at Johns Hopkins Medicine, said employees are given pre-employment eye exams to determine the health of the eye prior to working in the labs. In the case of an incident, she said, workers are screened to determine whether optical radiation caused a change in vision.

– TJB

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)