OSHA's Top 10 most cited violations

Growing data and changing inspection strategies

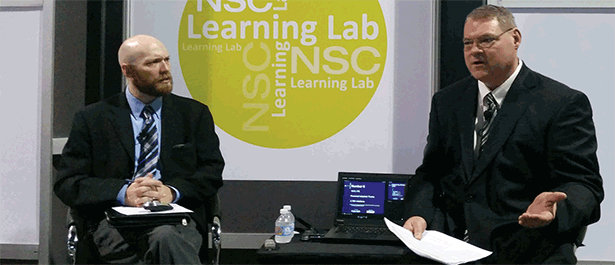

Q & A with OSHA's Patrick Kapust

Patrick Kapust (pictured, right) is the deputy director of OSHA’s Directorate of Enforcement Programs, where he leads a staff supporting the agency’s mission of standards enforcement. Kapust – who has been with OSHA for nearly 25 years – answered questions from Safety+Health Senior Associate Editor Kyle W. Morrison (on left) about recent changes to how OSHA measures enforcement activities, as well as workplace injury trends.

Safety+Health: At the 2015 National Safety Council Congress & Expo, OSHA administrator David Michaels announced that the agency would be moving away from counting the number of inspections it conducts. Instead, OSHA said it intends to measure “enforcement units,” with complicated inspections weighted higher than other less- time-consuming inspections. Can you explain how this system will work and what OSHA hopes to accomplish by using this new metric?

Patrick Kapust: The new enforcement weighting system assigns greater value to complex inspections that require more time and resources. The new system will allow for more strategic planning and measurement of inspections, and ensure that all workers are equally protected, regardless of the industry they work in. Routine inspections count as 1 “Enforcement Unit,” while those requiring greater resources – such as those involving musculoskeletal disorders, chemical exposures, workplace violence, and process safety management violations – count anywhere from 2 to 8 units. The values are based on historical data and will be monitored and adjusted as necessary.

S+H: What should employers expect under this new tallying system? Could employers in some industries find that inspections take longer and yield more citations?

Kapust: Employers should already know that OSHA may conduct inspections and issue citations for any sort of serious hazard, such as musculoskeletal disorders, workplace violence or exposures to chemicals – whether or not we have a specific applicable standard. We continue to encourage employers to abate hazards before an OSHA inspection and, more importantly, before a worker gets hurt.

As OSHA launches this new system, it is important to recognize what will not change. Whether it is to respond to a worker complaint alleging exposure to serious workplace hazards, investigate the occurrence of a severe injury or illness, or implement an enforcement emphasis program, all inspections will receive OSHA’s full commitment and effort to address relevant safety and health issues.

S+H: In January, a new rule went into effect requiring employers to report to OSHA all work-related fatalities within eight hours, and all work-related in-patient hospitalizations, amputations and losses of eyes within 24 hours. What has OSHA learned from these reports?

Kapust: Before 2015, employers were only required to report to OSHA work-related fatalities or incidents in which three or more workers were hospitalized. Often, when we conducted inspections of the worksites involved in these tragic events, we found that they had previous serious injuries and amputations that we had never known about. These injuries were red flags that there were serious hazards in this workplace that needed to be prevented.

Information gathered through the new reporting requirements was incorporated into OSHA’s updated National Emphasis Program on amputations and led the agency to develop a fact sheet on hazards from food slicers and meat grinders used in grocery stores, restaurants and delis.

Through the first nine months of this new reporting policy, we have already received more than 8,700 reports. We are triaging every call and initiating inspections in about a third of reported incidents – but we are engaging with every employer. We expect employers who we are not inspecting to conduct their own investigation and let us know what changes they will make to prevent further injuries. Investigating a worksite incident – a fatality, injury or illness – provides employers and workers the opportunity to identify hazards in their operations and shortcomings in their safety and health programs and, more importantly, to identify and implement the corrective actions necessary to prevent future workplace injuries, illnesses and fatalities.

S+H: According to preliminary data in a recent Bureau of Labor Statistics report, fatal injuries among construction and agriculture workers increased in 2014. What is OSHA doing in response to these increases, and how do these fatal injuries relate to standards on the Top 10 list?

Kapust: Preliminary data from the Bureau of Labor Statistics does show construction fatalities up from 828 in 2013 to 874 in 2014. However, the fatality rate has dropped from 9.7 to 9.5 (per 100,000 full-time equivalent workers) over the same period, during which there has been an increase in construction starts. Falls continue to be the leading cause of construction fatalities and one of the most commonly cited OSHA standards. Therefore, OSHA continued the Fall Prevention Campaign and National Safety Stand-Down in 2014 and 2015. These efforts, which have reached millions of workers and employers on the importance of protecting workers from fall hazards, will continue in the future.

S+H: Musculoskeletal disorders account for one-third of all injuries and illnesses, and are especially prevalent among nurses. Although federal OSHA doesn’t have an ergonomics standard, and thus it wouldn’t be on the Top 10 list, the agency has issued citations for ergonomics violations through the General Duty Clause. What should employers be aware of regarding MSDs, and what enforcement efforts is OSHA undertaking to lower MSD injuries?

Kapust: The Bureau of Labor Statistics reported 34 percent of all lost workday (nonfatal) incidents in 2013 were musculoskeletal disorders. Digging deeper into the BLS numbers shows that most of the injuries were strains and sprains from overexertion. By far, workers in hospitals and nursing homes had the highest number of work-related MSDs, where the injuries often end their careers in health care. Other occupations with high MSD rates include transportation/material movement, construction, and production work. OSHA issued eight General Duty citations in fiscal year 2015 in cases where the employer did not address well-recognized ergonomic risk factors (three in poultry; two in grocery distribution; and one each in a nursing home, airline and housekeeping).

From 2012 to 2015, OSHA had a National Emphasis Program to address the leading causes of injuries in nursing homes, including resident handling. The program included extensive outreach to the industry, compliance assistance and hazard alert letters. Hazard alert letters are used to put employers on notice when OSHA identifies a hazard during an inspection, but the evidence gathered in the case is insufficient to support the issuance of a General Duty Clause violation. In these letters, OSHA provides the employer with a list of feasible abatement measures it can take to mitigate the hazards. Over the three years from 2012 to 2015, a total of 199 ergonomic hazard alert letters were sent to nursing home employers and 12 citations were issued for injuries related to resident handling. In June 2015, OSHA’s Assistant Secretary’s Office sent the regional administrators a memo broadening the impact of OSHA activities in the health care industry, focusing on hospitals and nursing/long-term facilities with in-patient care. The memo provides guidance for compliance officers to look at five serious hazards on any unprogrammed or programmed inspections in health care (i.e., all North American Industry Classification System Major Groups 622 ?[Hospitals] and 623 [Nursing and Residential Care Facilities]). The five hazards are workplace violence, tuberculosis, bloodborne pathogens, slip/trips/falls, and patient/resident handling. Also, the memo encourages assessment of other hazards (e.g., methicillin-resistant Staphylococcus aureus, multi-drug resistant organisms, hazardous chemicals, anesthetic gases and hazardous drugs). OSHA will continue to work with employers by providing guidance, outreach and compliance assistance to keep new and experienced workers on the job without injuries.

S+H: The Fall Protection Standard has topped the list for the past five years. What about this standard yields so many violations? What common employer mistakes does OSHA see?

Kapust: Fall protection is required above 6 feet in construction, and there are many phases of construction with potential exposure. Fall protection is widely recognized as a major hazard and is therefore often referred to OSHA. Nearly every [OSHA] region has an emphasis program on fall protection in an effort to make an impact. A lack of fall protection on a construction project is extremely hazardous and treated as such by compliance officers.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)