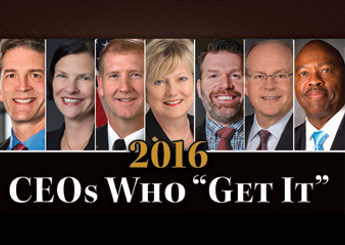

2016 CEOs Who 'Get It'

The National Safety Council recognizes seven leaders who demonstrate a personal commitment to worker safety and health

|

Intro Gerard Anderson Andrea E. Bertone Col. Michael Farrell

Carol Johnson Bill Koziel Edward J. Sheehan Jr. Phil Washington |

|

Edward J. Sheehan Jr.

President and CEO

Concurrent Technologies Corp.

Johnstown, PA

|

Accomplishments

CONCURRENT TECHNOLOGIES CORP. is an independent, nonprofit, applied scientific research and development professional services organization employing about 800 workers. Together with its affiliates, CTC leverages research, development, test and evaluation work to provide transformative, full lifecycle solutions. |

Why is safety a core value at your organization?

We genuinely care about our employees’ health and well-being. At CTC, our employees are our most important resource. That’s first and foremost. In addition, environment, safety and health is one of our key areas of expertise. We help other organizations implement safety, environmental health and wellness programs.

For instance, CTC operates the Department of Defense Safety Management Center of Excellence (DoD SMCX), which deploys safety management systems and programs that help Defense installations and agencies implement safety management systems with the goal of significantly reducing occupational injuries and illnesses. Many of these sites have achieved OSHA Voluntary Protection Programs STAR recognition.

OSHA VPP STAR sites enjoy the highest safety designation granted by OSHA to a worksite. VPP STAR sites have exemplary safety performance records, and they can achieve up to a 150 percent return on investment. In addition to helping other entities earn STAR status, CTC has applied for and earned VPP STAR recognition at our two largest facilities.

Through the DoD SMCX, CTC’s team has conducted more than 400 safety management system evaluations and performed more than 100 industrial hygiene assessments at the U.S. Army Public Health Command and U.S. Navy. Going above and beyond safety and health compliance is the foundation of any evaluation or assessment we do, and continues to be an ongoing focus at CTC.

Describe your personal journey to becoming a CEO who “gets it.” What experiences or lessons brought you to where you are now?

First, I want to emphasize that this recognition is a result of the commitment of the entire team who create and sustain a safe working environment at CTC. Our leadership team is committed to employee safety, and our employees are actively involved at all levels. Our proactive wellness programs have contributed to our overall success as well.

Early in my career I learned that mere safety compliance was not good enough. Going above and beyond regulatory compliance is necessary to achieving safety and occupational health performance. In addition, this performance-driven approach has contributed to the productivity, innovation and financial health of the organization. I also realized that above all, you have to have a positive safety culture. CTC employees are knowledgeable, empowered and committed to employee safety and health excellence.

Because CTC is fully vested in teaching other organizations about environmental health, safety and wellness, I’ve had the opportunity to work with some of the best safety experts in the country. Our safety and occupational health professionals do great work, and I’m honored that one of them nominated me for this recognition.

In her nomination, Lori Schroth, a senior safety and industrial professional, humbled me by remembering the ways she saw me promote our safety culture. For instance, she wrote that I integrate safety into all my correspondences. I walk through work areas and talk with employees and promote safety. Lori recalled that I encourage activities like Safety Days, Take Your Daughters and Sons to Work Days, and am actively involved with environmental health issues on an as-needed basis. She concluded, “He was a supporter for OSHA VPP, and we couldn’t have achieved that recognition or sustained it without him.” Leadership commitment is one of the pillars to a successful safety management system and VPP Star recognition. Hearing that felt as good as winning this award!

What is the biggest obstacle to safety at your organization, and how do you work to overcome it?

I am proud to say that we do not have any obstacles at CTC when it comes to safety. Living the CTC brand means that we look out for each other, and we do what is right. We go above and beyond regulatory requirements to ensure our employees return to their families after each workday is complete. With that said, we do have areas where we have more potential for mishaps than others.

When I think about CTC’s need for performance-based safety protocols, I immediately think about our high bay where advanced metalworking technologies, friction stir welding, advanced laser robotics coatings removal, and other scientific and engineering work is performed. Research and development and new technology may introduce new hazards to our employees. CTC’s proven processes ensure that all environmental, safety and occupational health hazards are mitigated.

Additionally, we have extensive travel within CTC to support our clients all over the world. Our winters can be on the extreme side and, ensuring our employees can enter and exit our facilities safely is paramount.

How do we overcome any safety obstacles? We are committed to our safety management system approach and the four pillars of VPP: leadership commitment and employee involvement, worksite analysis, hazard prevention and control, and safety and health training. Leadership is engaged at all levels. Employees are involved in safety self-inspections, EHS committees, job safety analysis development and near-miss reporting. We have dedicated safety, environmental and training professionals that provide compliance support, coaching and mentorship. Our robust ESOH program, policies and procedures ensure that safety is addressed not only at the corporate level, but is driven down to the project level as well. All policies and procedures are reviewed annually to ensure they are performing at a level needed to proactively prevent employee mishaps. Near misses are investigated and policies and procedures can be updated at that time to ensure any new hazards are identified and mitigated immediately.

Finally, as President and CEO of CTC, it is my responsibility to ensure that safety and health is fully resourced based on regulatory requirements and our commitment to OSHA VPP.

How do you instill a sense of safety in employees on an ongoing basis?

At CTC, safety is part of our brand DNA. From the very first day of employment, new employees receive orientation on safety, our VPP recognition program and how safety is a core value of our organization.

Safety is promoted through our employee website, and special safety considerations are discussed at the beginning of all meetings. Visitors to the organization are briefed on our safety requirements and evacuation procedures should an emergency occur. Our EHS committee is led by employees outside of the safety office to ensure the program is truly employee driven.

Additionally, our employees who do the work are also involved in identifying the hazards and mitigation through our job safety analysis program. Our employee safety committee is also very active and visible through a quarterly newsletter and regular online articles on multiple safety topics.

During National Safety Month each June, we conduct safety days with fun activities – hands-on training, demonstrations, contests and prizes – that keep people thinking about safety awareness. Employees at offsite locations can participate through our unique virtual booth. I set aside time to attend each year because I think it’s important personally to stay on top of safety issues, and it’s important to let employees know that I make safety a priority. Talking with employees, knowing their names and what they do at CTC, and sharing a laugh with them as I miss a golf putt, ring toss or something like that keeps everything relevant and in perspective!

How does your organization measure safety? What are the leading indicators that show you how safe your organization is, and where do you see room for improvement?

Over the past year, CTC had two separate streaks of five consecutive months without a recordable injury and achieved rates that were more than 50 percent below the national industry average. Because there is always room for improvement, our program involves as many employees as possible through a safety self-inspection component. Last year, our employees completed 865 safety self-inspections and submitted 130 safety suggestions.

In March 2015, our employees were recognized by the National Safety Council for two milestone achievements. CTC was presented with the Perfect Record Award for working 3,273,475 hours between March 4, 2013, and Dec. 12, 2014, without a lost-time accident. In addition, the National Safety Council presented CTC with the Million Work Hours Award for the same period and total hours.

What role does off-the-job safety play in your organization’s overall safety program? What types of off-the-job safety and health programs does your organization offer to employees?

Each year, CTC hosts an annual hazardous waste collection day in one of our Johnstown parking lots. This year, we collected 13.4 tons of hazardous waste in one day, for an 11-year total of more than 130 tons.

We offer free American Red Cross Adult First Aid/Cardiopulmonary Resuscitation/Automated External Defibrillator classes to employees, and right now nearly 10 percent of all of our employees are certified. They’re acknowledged on our intranet, and through an in-house article we have thanked them for their willingness to help others in need.

Each and every month our EHS professionals provide safety tips that include off-the-job topics to keep our employees safe while at home or at play. Our wellness programs provide discounts to fitness centers along with a variety of programs to keep employees safe and healthy. We ensure that flu shots are available to all employees free of charge, and dependents at a reduced rate, right here in our facilities. Our employees are priority No. 1 whether they are at work or off the job.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)