Key charting to manage lockout

How does safety padlock key charting help me manage my lockout padlock system?

Responding is Bill Belongea, safety services program manager, The Master Lock Co., Oak Creek, WI.

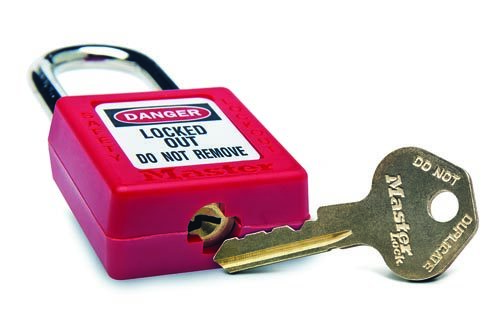

OSHA’s Lockout/Tagout Standard (1910.147) states that the operating key for a lockout padlock must be under the control of the person who applied the lock. So, it’s critical for facilities to reduce unintended key duplication by properly assigning and managing keys to ensure only authorized personnel are operating the safety padlocks assigned to them.

One method for efficiently managing safety padlocks is key charting or, in other words, maintaining a record of key codes that are produced for a facility. This can be done by the lock manufacturer. The facility then can track and manage who is assigned the lock and key associated with each key code, which is essential for compliance and employee confidence.

Charting specifically addresses the need and provides the ability to assign locks and keys to authorized personnel. When done well, charting helps ensure proper execution of the facility’s keying strategy and drives operational efficiencies. Two commonly implemented key configurations are “keyed different” and “keyed alike,” which differ in the following ways:

Keyed different: A lock that has its own unique key is keyed different. If an employee is most commonly applying a single lock, a keyed-different job lock is recommended. If four locks are commonly applied for each job, keyed-different locks are sufficient, but there’s one chance in four the first key pulled out of an employee’s pocket will open the lock. Safety can also be compromised when keyed-different locks aren’t charted properly, creating the chance of a lockout device being released too soon and potential for equipment to become reenergized early.

Keyed alike: A set of keyed-alike locks will open with a shared key. The more locks that are applied, the more important it is to use a keyed-alike system. Keyed-alike job locks are common in the execution of group lockout. Job locks are often structured in sets of five, and all the way up to hundreds of locks in major turnarounds in the oil and gas industry. When job locks are keyed alike, charting provides an accurate record to be able to reorder a specific key code for a replacement lock in the set.

No matter what keying method is chosen, managing keys within a facility of any kind is critically important. The integrity and security of lockout can be compromised when other keys in the facility can open another authorized employee’s padlock. Master keys and duplicate keys in the facility – when intentional – need to be carefully managed and should be explicitly outlined within a site-specific lockout policy.

Although safety managers could track key codes on their own, manufacturers provide charting as a complimentary service for registered end users. By using a vendor to manage key charting, new lock orders are assigned unique key codes, ensuring no two locks open with the same key – keeping the workers’ safety in their control and allowing safety managers to reorder a charted code when an employee needs additional locks.

Editor's note: This article represents the independent views of the author and should not be construed as a National Safety Council endorsement.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)