Creating an ergonomic safety knife program

How do modern safety knives improve ergonomics and overall workplace safety?

Responding is Laura Calder, vice president of marketing, Safety Products Global, Irvine, CA.

A growing number of companies are paying attention to ergonomics. Why? Good ergonomics leads to good economics. Improving workplace ergonomics offers a multitude of benefits, including increased efficiency, a reduction in costs associated with work-related injuries and enhanced workplace safety.

From lacerations to musculoskeletal disorders, work-related injuries are costly, yet preventable. According to OSHA, employers should expect to pay an average of $46,000 in direct and indirect costs per laceration injury. As environments have become more fast-paced with higher productivity expectations, it’s critical that employers support their workers with tools and processes that help protect them.

Modern safety knives can play a significant role in improving workplace ergonomics, from distribution centers to manufacturing to grocery and retail stores. Over the past 50 years, the traditional utility knife has radically evolved in design to better protect the user from injury.

Frameworks such as the NIOSH Hierarchy of Controls have directly influenced the expansion of this category, from improved worker training to the development of new safety knife and blade features.

Safety knives are commonly used to cut various types of corrugated boxes, stretch wrap, tape and banding.

In many industrial environments, safety knives are used by workers hundreds of times a day, demonstrating the necessity for ergonomic features to help prevent injury and fatigue that can lead to reduced productivity.

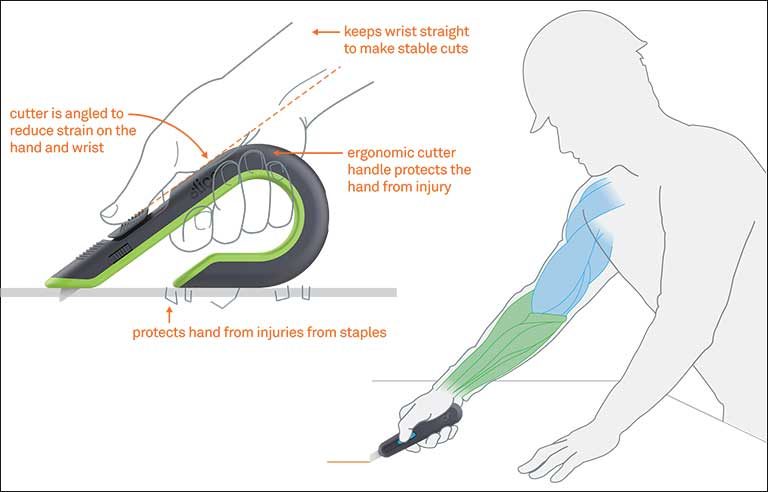

When evaluating safety knife options, users can look for a few design features for improved ergonomics. First, ergonomic features integrated into the handle improve operator control and comfort. Features such as squeeze-handle triggers help reduce hand fatigue and are ideal for workers wearing safety gloves. The overall handle shape, button or slider design and position, and over-mold can help reduce hand and wrist strain and should be considered based on the hand size of the users.

Second, users can select between different blade types and blade exposures based on their level of safety requirements. For example, utility knives fitted with blades that are safe to the touch offer a very high level of safety. Concealed blade designs help shield the user from the blade, and safety knives with integrated blade guards and blade retraction technologies limit the blade exposure.

As a first step to selecting the best-fitting safety knife program, employers should conduct a knife audit with a safety knife expert. Despite the assortment of safety knife solutions, none is a one-size-fits-all. A safety knife audit analyzes critical operational factors – including workforce demographics, materials being cut, safety requirements and environments – to prescribe a safety knife program and training process that correctly fits the organization’s needs. For easier implementation, organizations should consider sampling and piloting new safety knives with workers to solicit feedback and ensure correct use. This holistic approach of pairing a safety knife program with the organization is critical to offering an ergonomic solution and creating a safer, more productive workplace.

Editor's note: This article represents the independent views of the author and should not be construed as a National Safety Council endorsement.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)